ENVIRONMENT

Supply Chain

A responsible supply chain is a cornerstone of APIC Group’s commitment to sustainability and ethical business practices. We believe in working closely with our suppliers to enhance quality standards, promote transparency, and minimize environmental impact throughout our supply chain. By collaborating with our suppliers, we aim to ensure that the products and services we deliver meet the highest standards of quality, safety, and ethical sourcing.

One of our key initiatives is to prioritize local sourcing whenever feasible, supporting local economies and communities while reducing carbon emissions associated with transportation. By buying local, we strengthen relationships with local suppliers, contribute to the growth of regional businesses, and foster economic resilience in the communities where we operate.

In alignment with APIC Group’s Environmental, Social, and Governance (ESG) policy, we place a strong emphasis on supporting women-owned and led third-party suppliers. Recognizing the importance of diversity and gender equality in the business ecosystem, we actively seek out opportunities to engage with women entrepreneurs and businesses. By prioritizing women-owned and led third parties, we aim to empower women economically, promote gender equality, and foster inclusive growth within our supply chain.

Additionally, as of 2024, APIC Group requires that our suppliers align with our ESG Policy when they sign or accept any agreement or purchase order issued by any of our subsidiaries that commits them to upholding ethical labour practices and governance, environmental stewardship, and social responsibility. The agreement can be found on APIC’s website.

Energy

Total energy intensity

0.84 MWh per ton of product

APIC Group has maintained a longstanding commitment to energy-related initiatives, with a particular emphasis on solar energy. The group has taken significant steps towards enhancing sustainability and environmental preservation, considering solar energy as one of its primary focal points. Through investments and initiatives in the field of solar energy, the group aims to reduce harmful environmental emissions and promote sustainability within its operations. These efforts reflect APIC Group’s enduring dedication to achieving sustainable development and preserving natural resources for future generations.

LED Lighting

As part of our commitment to energy efficiency, APIC Group has transitioned to LED lighting systems in its facilities. LED lights consume significantly less energy than traditional lighting sources while providing superior illumination quality. By replacing outdated lighting fixtures with energy-efficient LEDs, we have reduced energy consumption and operational costs while enhancing lighting performance and longevity.

Refrigeration Unit Sensors

APIC Group has implemented advanced sensor technology in its refrigeration units to optimize energy usage. These sensors monitor temperature levels and adjust cooling settings accordingly, ensuring that energy is used efficiently while maintaining optimal storage conditions for perishable goods. By reducing unnecessary energy expenditure, these sensors contribute to significant energy savings and environmental conservation.

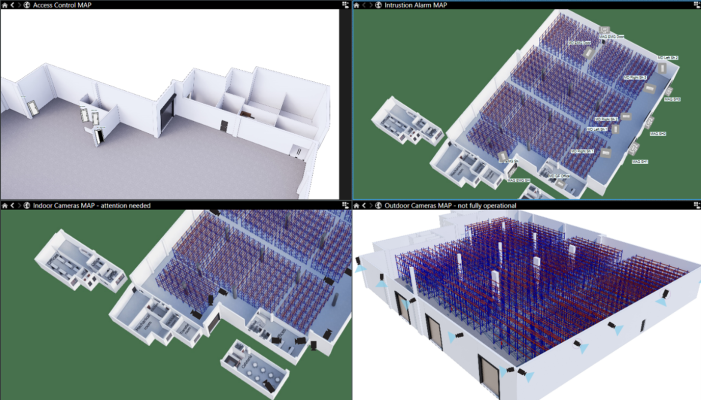

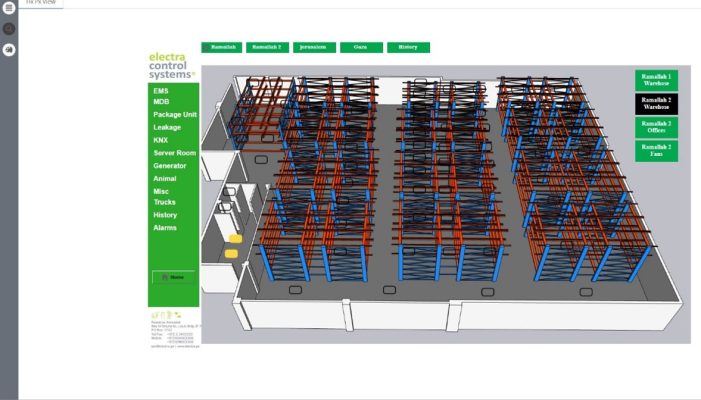

Building Management Systems (BMS)

Our facilities are equipped with advanced Building Management Systems that monitor and control various building systems, including HVAC (Heating, Ventilation, and Air Conditioning), lighting, and energy consumption. These systems utilize smart technology and automation to optimize energy usage based on occupancy levels, time of day, and environmental conditions. By dynamically adjusting energy settings and schedules, BMS helps minimize energy waste and maximize efficiency across our buildings.

Energy-Efficient Machinery

APIC Group invests in state-of-the-art, energy-efficient machinery and equipment across its manufacturing and production facilities. From industrial machinery to manufacturing processes, we prioritize the adoption of energy-efficient technologies that minimize energy consumption without compromising productivity or product quality. By integrating energy-efficient machinery into our operations, we reduce our carbon footprint and contribute to a more sustainable manufacturing environment.

Awareness Posters

APIC Group fosters a culture of energy conservation and awareness among employees through informative posters and signage strategically placed throughout our facilities. These posters highlight energy-saving tips, best practices, and reminders to turn off lights and equipment when not in use. By promoting employee engagement and accountability, these awareness campaigns contribute to a collective effort to reduce energy waste and promote sustainability.

APIC Group has made significant strides in reducing its fuel consumption by progressively transitioning towards hybrid and electric vehicles. Recognizing the environmental impact of traditional fuel-powered cars, the group has actively embraced more sustainable transportation options. By incorporating hybrid and electric vehicles into its fleet, and the Palestinian Market, APIC Group aims to minimize greenhouse gas emissions and decrease its overall carbon footprint. This transition underscores APIC Group’s commitment to environmental stewardship and sustainability, demonstrating its dedication to adopting innovative solutions for a cleaner and greener future.

APIC Group has made significant strides in reducing its fuel consumption by progressively transitioning towards hybrid and electric vehicles. Recognizing the environmental impact of traditional fuel-powered cars, the group has actively embraced more sustainable transportation options. By incorporating hybrid and electric vehicles into its fleet, and the Palestinian Market, APIC Group aims to minimize greenhouse gas emissions and decrease its overall carbon footprint. This transition underscores APIC Group’s commitment to environmental stewardship and sustainability, demonstrating its dedication to adopting innovative solutions for a cleaner and greener future.

Energy consumption and production in MWh

Inclusive of 50% of solar energy produced and sold through Qudra, a subsidiary of National Aluminum and Profile Company.

Fuel consumption in liters (transportation)

Siniora Food Industries in Palestine Wins the 2023 National Sustainable Energy Pioneers Award

It is a source of pride and honour that in 2024, Siniora Palestine has been awarded the National Sustainable Energy Pioneers Award in the Industrial Sector for 2023.

This achievement reaffirms Siniora Palestine’s commitment to innovation and sustainability, as they continuously adopt the latest energy-efficient solutions to enhance energy use and reduce waste.

Recognized by the United Nations Industrial Development Organization (UNIDO), this award is a testament to the dedication and hard work of Siniora Palestine’s team in implementing sustainable energy solutions that boost the company’s competitiveness and productivity.

The Palestine Automobile Company Leads the Way in Green Transportation in Palestine

As a pioneer in sustainable mobility, the Palestine Automobile Company is driving the future of green transportation in Palestine. With 65% of total sales consisting of environmentally friendly vehicles, the Palestine Automobile Company demonstrates a firm commitment to reducing carbon emissions and fostering a cleaner, greener future.

The Palestine Automobile Company holds the #1 position in overall sales of Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs) in Palestine, reinforcing its leadership in the shift toward sustainable transportation.

By prioritizing electric and hybrid solutions, the Palestine Automobile Company is not only reshaping the automotive landscape but also aligning with the global sustainability agenda and supporting Palestine’s sustainable development goals.

Siniora Food Industries in Jordan Enhances Energy Efficiency in Expansion Project

As part of its ongoing commitment to sustainability, in 2024, Siniora Food Industries Jordan has integrated energy-efficient equipment and low-emission technologies into its latest expansion project. These upgrades are designed to reduce environmental impact while enhancing operational efficiency. Siniora Food Industries Jordan upgraded the cooling system compressors by replacing the old system with screw technology compressors equipped with inverters, ensuring optimized energy use and reduced power consumption. It also integrated the main cooling systems with the Building Management System, enabling continuous tracking and real-time performance optimization to ensure maximum efficiency and sustainability.

Unipal General Trading Company Installs Solar Panel System to Power DC Compound

Unipal has taken a major step toward sustainability with the installation of a solar panel system on the roof of their Distribution Centre in Ramallah, making significant strides in reducing its carbon footprint. The new system covers 30% of the total power consumption for the Distribution Center, including energy needs for the cold rooms, making a substantial impact on energy efficiency and environmental responsibility.

As part of their commitment to expanding sustainable practices, Unipal is already in the planning stages to extend the system to significantly increase their renewable energy capacity, aiming to cover 85% of the total power consumption for all compounds, including the new building.

This move marks a key milestone in APIC Group’s ongoing efforts to reduce energy reliance on non-renewable sources, driving both environmental impact reduction and long-term operational cost savings.

Water

Total water intensity

0.42 m³ per ton of product

APIC Group recognizes the critical importance of water efficiency and responsibility, particularly in regions like Palestine, which face significant water stress exacerbated by illegal occupation-related challenges. Operating in such areas underscores our commitment to sustainable practices and responsible water management. In light of these circumstances, APIC Group has implemented stringent measures to optimize water usage across its operations. These initiatives include:

Water Recycling and Reuse:

APIC Group has invested in advanced water recycling technologies to minimize water wastage and maximize reuse opportunities. By treating and recycling water used in various processes, we reduce our reliance on freshwater sources and alleviate pressure on the local water supply.

Water Efficiency Practices:

In food production activities, APIC Group employs efficient techniques to minimize water consumption while ensuring optimal productivity. Sprinkler systems and moisture monitoring are among the methods utilized to achieve water savings without compromising product quality.

Continuous Improvement:

APIC Group remains committed to continuous improvement in water efficiency and responsibility. We regularly assess and optimize our water management practices, incorporating technological advancements and innovative solutions to further enhance our environmental performance.

Siniora Food Industries in Palestine Reduces Water Consumption by 21% – A Milestone Achievement in Sustainability

At Siniora Palestine, sustainability is more than just a goal; it’s a responsibility. Driven by their commitment to conserving natural resources and reducing their environmental footprint, Siniora Palestine’s dedicated team embarked on a journey to optimize water usage across food production processes. The result is a remarkable 21% reduction in water consumption, achieved through a series of innovative projects and collaborative efforts.

Water is a critical resource in food production, and the West Bank is considered a water-stressed area. Water is used extensively for cleaning, processing, and maintaining hygiene standards. As part of their broader sustainability strategy, Siniora Palestine identified water conservation as a priority area. The challenge was to maintain their high standards of quality and safety while significantly reducing water usage.

A multidisciplinary team of engineers, operators, and management came together to identify opportunities for improvement. Over the course of several months, the team implemented targeted projects, each designed to tackle specific areas of water consumption.

Some key initiatives included:

- Advanced Cleaning Systems: Upgrading to high-efficiency cleaning systems that used less water without compromising hygiene.

- Recycling & Reuse: Installing water recycling systems to repurpose water from non-critical processes.

- Awareness Campaigns: Educating staff on water-saving practices, fostering a culture of conservation.

- Continuous Monitoring: Implementing real-time monitoring systems to identify and address inefficiencies promptly.

The results exceeded expectations. Through these projects, Siniora Palestine successfully reduced water consumption by 21% compared to previous year, saving thousands of litres of water. This achievement not only underscores Siniora Palestine’s commitment to sustainability but also positions them as a leader in responsible food production.

Siniora Food Industries in Jordan Conducts Water Audit and Launches First Water Treatment Plant

As part of its commitment to sustainability and resource efficiency, in 2024, Siniora Food Industries in Jordan conducted a comprehensive water audit in collaboration with an environmental consulting firm. During the audit, a water mapping system was developed to track water distribution, purification, treatment processes, and optimal usage in compliance with industry standards. Additionally, the audit identified water conservation opportunities across all operations and outlined key projects and mechanisms to ensure efficient water consumption.

This builds on its efforts in 2022 and 2023, where Siniora Jordan took a major step forward by establishing a state-of-the-art industrial wastewater treatment unit at its Amman facility, with an investment exceeding 500,000 JOD and an operational capacity of more than 240 m³/day. To ensure optimal efficiency, the company trained and qualified a specialized team, implemented standard operating procedures, and introduced monitoring and follow-up models to meet required water quality standards. Additionally, precautionary measures were put in place to prevent any non-compliance or environmental risks.

Also in 2024, Siniora Jordan started piloting water reclamation with a capacity of 12 m³/day for use in its cooling towers, significantly reducing water consumption and minimizing discharge into sewage systems with hopes to scale in the coming years.

Water consumption (cubic meters)

0

APIC

3,899

Siniora Palestine

4,522

Siniora Jordan

0

MSS

24,077

Polonez

0

PAC

4,854

NAPCO

0

UNIPAL

37,352

Total

Waste

Total waste diverted from disposal through partnering with companies that reuse or recycle

Total waste intensity

0.04 tons of waste per ton of product

APIC Group is deeply committed to effective waste management practices across all its operations. Recognizing the importance of environmental sustainability, APIC has implemented comprehensive waste management strategies aimed at minimizing waste generation, promoting recycling, and ensuring proper disposal of residual waste.

One key aspect of APIC Group’s waste management approach is waste reduction through efficient processes and resource utilization. By optimizing production methods and adopting innovative technologies, APIC endeavours to minimize waste generation at the source, thus reducing its environmental footprint.

In addition to waste reduction, APIC Group places a strong emphasis on recycling and reuse initiatives. Through partnerships with available recycling companies and waste management service providers, APIC ensures that recyclable materials such as paper, wood, batteries, cardboard, and metal are collected, processed, and reused wherever possible.

Furthermore, APIC Group implements proper disposal methods for non-recyclable waste, adhering to regulatory guidelines and environmental best practices. Waste that cannot be recycled is disposed of responsibly, utilizing certified waste management facilities and techniques to minimize environmental impact.

APIC Group Takes Steps Towards Eliminating Single-Use Plastics

As part of its commitment to sustainability and environmental responsibility, APIC Group has taken significant steps toward eliminating single-use plastics across its operations. This initiative was launched on 28 July 2024 in commemoration of World Conservation Day and in alignment with global efforts to reduce plastic waste and promote eco-friendly alternatives.

The company is actively working towards eliminating the procurement of single-use plastics such as plastic water bottles and cups, prioritising available sustainable packaging solutions, encouraging the use of biodegradable and recyclable materials, and adopting waste reduction strategies. Additionally, APIC Group is working closely with suppliers, employees, and stakeholders to foster a culture of sustainability, ensuring that eco-conscious practices become an integral part of its business operations. This is reflected in APIC Group’s newly developing Procurement Guidelines, Marketing and Labelling Guidelines, and Waste Management Planning Guidelines.

The Procurement Guidelines adopted in 2024 require APIC’s subsidiaries to revise their procurement policies to include environmental, social and governance implications each according to their needs and conditions. Conditions include applicable regulations and what is available in the market. Revised policies include prioritising eco-friendly and nature-based solutions, including criteria in procurement evaluations such as mandatory alignment with APIC Group’s Compliance with Environmental, Social, Governance Agreement, setting maximum percentages of product /packaging that ends up in waste, giving preference to products/services with innovation in sustainability, businesses that are women-owned or led, companies that have social responsibility programmes, etc.

Marketing and Labelling Guidelines adopted in 2024 are covered under the Customer Health and Safety Section.

Waste Management Planning Guidelines adopted in 2024 require APIC’s subsidiaries to develop/ revise their Waste Management Plans requiring data collection on waste produced by type and weight, identification of waste sources and final destinations, and finding solutions for waste reduction and recycling/re-use with set indicators and timelines for implementation.

Recycling Batteries and Car Oil at the Palestine Automobile Company

As part of its commitment to environmental sustainability, PAC has launched a comprehensive recycling program for batteries and automotive oil. This initiative addresses the critical need for responsible disposal of hazardous materials while aligning with the company’s broader sustainability objectives.

Battery Recycling Program

PAC has established a partnership with a leading car battery manufacturer to ensure the safe collection and recycling of used batteries. This initiative prevents hazardous chemicals from entering landfills and facilitates the efficient reuse of lead components. Additionally, PAC is actively negotiating with another company to manage the end-of-life disposal of lithium batteries used in electric and hybrid vehicles, further reinforcing its commitment to responsible recycling practices.

Automotive Oil Recycling

PAC has also partnered with specialized entities that employ eco-friendly processes to collect and recycle used automotive oil. This initiative mitigates the risk of soil and water contamination while enabling the purified oil to be repurposed for various industrial applications, reducing overall environmental impact.

Through these strategic initiatives, PAC is playing a vital role in minimizing its environmental footprint and fostering a culture of sustainability within the automotive and energy sectors.

National Aluminium and Profile Company Leads in Sustainability by Reusing Aluminum in Hot Direct Extrusion

NAPCO has successfully implemented an innovative approach to reusing aluminum in its hot direct extrusion process. The idea behind the development lies in keeping the aluminum inside the feeding chambers and maintaining the complete details of the die after the production process is finished. The die is then stored in this condition without the need to remove the aluminum residues from the dies using chemical or mechanical methods.

This developmental modification has improved overall performance by speeding up the work process and reducing activities and movements within the workflow, leading to cost reductions.

This strategic shift has led to:

- 60% reduction in mechanical work required for dismantling frames

- 60% decrease in chemical processes needed to melt aluminum using NaOH, saving 3,000 kg of chemicals annually

- Elimination of chemical treatment, transport, and disposal costs of NaOH, contributing to a cleaner, more sustainable operation

- Increased production capacity by 39 tonnes annually, thanks to time saved from reduced dismantling and chemical processes

- Higher aluminum quality and reduced scrap, ensuring better resource utilization

- Financial savings of USD 140,000 annually, reinforcing both environmental and economic benefits

This initiative was rewarded with a CEO Award in 2024 honouring NAPCO’s continued efforts to set new standards in sustainable manufacturing, demonstrating how innovation can drive both business success and environmental responsibility.

Additionally, in 2024, NAPCO took another significant step toward sustainability by replacing wood pallets with durable metal pallets. This transition not only reduces wood consumption but also enhances pallet lifespan, lowers waste, and improves logistics efficiency.

Siniora Food Industries Company Palestine 2024 Waste Reduction Initiatives

As part of its commitment to sustainable operations and waste reduction, Siniora Palestine has introduced two key initiatives to enhance resource efficiency and environmental responsibility.

- Buy-Back Agreement for Wood Pallets – Siniora Palestine has implemented a pallet return system, ensuring that wooden pallets are reused instead of discarded. This initiative reduces wood waste, lowers costs, and extends the lifecycle of pallets, contributing to a more circular supply chain.

- Upgrading Cardboard Recycling – through improved sorting and monitoring, Siniora Palestine now collect and prepare approximately 80 pallets of cardbaord monthly, significantly reducing material loss. These pallets are sold to a dedicated recycling company, ensuring sustainable processing and generating steady revenue.

- Replacement of Cardboard with Reusable Containers – To minimize packaging waste, Siniora Palestine has replaced a portion of traditional cardboard boxes with reusable containers for deliveries to distributors. This shift significantly reduces single-use packaging, lowers environmental impact, and enhances delivery efficiency.

- Streamlining Can Handling and Reducing Waste – Siniora Palestine implemented an innovative process for managing empty metal cans and defective cans from production lines. These cans, which would otherwise be discarded, are now collected, compressed, and recycled, turning potential waste into valuable resources. Each month, between 1.5 to 2 tons of these metal cans are sorted to ensure that all cans are free from additives or residues that might affect recycling quality. Defective cans are separated, and all materials are compressed using high-efficiency presses, significantly reducing their volume. This step not only optimizes storage space but also facilitates easier transportation. The compressed cans are sold to recycling companies, providing an additional revenue stream for operations.

These sustainability-driven initiatives reinforce Siniora Palestine’s leadership in responsible business practices, demonstrating a strong commitment to waste reduction, resource conservation, and eco-friendly distribution solutions.

Siniora Food Industries Company Jordan 2024 Waste Reduction Initiatives

Siniora Jordan has a comprehensive Waste Management System to ensure the safe disposal and management of waste generated from both production and supporting operations. The system classifies waste according to local regulations and its placement within recycling systems. Key highlights of the system include:

- Waste tracking forms designed to monitor all types of waste

- Training materials incorporated into the annual employee training plans for 2023-2024

- A partnership agreement with a recycling organization for office paper recycling

- Buy-Back Agreement for Wood Pallets. Approximately 500 new pallets are now secured each month for warehouse use in return for 2,700 used pallets instead of getting discarded as waste.

- Recycling Competition (“Instead of Throwing It Away… Recycle It!”) – Employees collected over 1,000 kg of paper as part of an initiative to promote recycling and encourage active participation in sustainability efforts. Winners were awarded cash prizes, further motivating engagement.

Other Waste Reduction Initiatives in 2024

- In 2024, APIC Amman launched an office paper recycling initiative, successfully recycling 221 kg of paper reinforcing our commitment to sustainability and waste reduction.

- Unipal has transitioned to sustainable document disposal in line with sustainability policies, where documents are destroyed through shredding and recycling through a third-party.

- Unipal implements a pallet refurbishment and reuse program by assigning skilled warehouse employees to repair and maintain the pallets.

- MSS has made significant strides in reducing its environmental impact by revising its packaging strategies to minimize cardboard usage. The company introduced a wider range of packaging sizes, allowing for more efficient use of cardboard without compromising product protection or integrity. The new packaging is more compact and uses less filling material, further reducing waste.

Waste Produced and Disposed, Non-Hazardous, in tons

4

APIC

802.7

Siniora Palestine

1,640

Siniora Jordan

12

MSS

644

Polonez

103

PAC

125.5

NAPCO

15

UNIPAL

3,346

Total

CO2 Footprint

Total emissions intensity

0.13 tons per ton of product

APIC Group is dedicated to reducing its emissions footprint as part of its commitment to environmental sustainability. Understanding the importance of mitigating greenhouse gas emissions for a healthier planet, APIC has implemented various initiatives aimed at reducing emissions across its operations.

One key strategy employed by APIC Group is reducing energy consumption and the adoption of cleaner and more efficient energy sources, outlined in the Energy section of this report. The company also invests in renewable energy technologies such as solar power, and makes them available to the market, to reduce reliance on fossil fuels and lower carbon emissions associated with energy consumption.

Moreover, APIC is committed to continuously monitoring and tracking its emissions performance to identify opportunities for further reduction. The company conducts regular assessments, utilises advanced filtration mechanisms, and audits to measure its emissions output and identify areas for improvement. By setting emission reduction targets and implementing emission reduction initiatives, APIC strives to continuously reduce its environmental impact and contribute to global efforts to combat climate change.

Scope 1 emissions (tCO2e)

27

APIC

5,088

Siniora Palestine

2,184

Siniora Jordan

292

MSS

2,407

Polonez

72

PAC

1,350

NAPCO

292

UNIPAL

11,712

Total

Biodiversity

APIC Group recognizes the critical importance of biodiversity conservation and is committed to promoting biodiversity across its operations. As a responsible corporate citizen, APIC understands that preserving biodiversity is essential for the health of ecosystems, the sustainability of natural resources, and the well-being of communities.

One way APIC contributes to biodiversity conservation is through responsible land management practices. The company ensures that its operations are conducted in a manner that minimizes impact on natural habitats and ecosystems, and actively endeavours to confine its operations to designated industrial zones.

APIC recognizes the importance of raising awareness about biodiversity conservation among its employees, stakeholders, and the broader community. The company provides training to its employees to promote understanding of biodiversity issues and encourages sustainable practices both within and outside the organization.

Biodiversity at Siniora

Tree Planting on World Conservation Day 2024

In commemoration of World Conservation Day 2024, and one year since the launch of the sustainability programme at APIC Group, employees at APIC Palestine, Siniora Palestine, MSS, and NAPCO took part in a meaningful environmental initiative, combining tree planting with a community clean-up to promote sustainability and conservation.

Tree Planting: Employees and community members gathered to plant a variety of trees on company grounds, contributing to biodiversity and helping combat carbon emissions. The event focused on restoring natural habitats and enriching the environment for future generations by planting more than 200 trees.

Surrounding Area Clean-Up: Volunteers worked together to clean up litter and waste from public areas, enhancing the beauty of local landscapes and ensuring a safer, cleaner environment for wildlife and the community.

Community Engagement: The event fostered a sense of teamwork and environmental responsibility among participants, encouraging greater involvement in conservation efforts.